PRODUCT CATEGORY

T400 dual system solvent recovery machine

Double system solvent recovery machine,Main functions and introduction of the equipment

1: Water-cooled continuous solvent recovery machine, feed 450 liters, total tank capacity of 550 liters, power 32KW, recovery of 100-200 liters of solvent per hour, recovery of more than 95% of the solvent

2: Pneumatic and manual slag discharge dual protection, the thickness of the barrel is 6MM, SUS304 stainless steel, and the slag discharge port is a DN100 pneumatic valve

3: An explosion-proof display and an explosion-proof mouse are a safer and faster recovery device

4: Configure spiral wound tube condenser, inner tube 316L, outer shell 304 stainless steel, thickness 1MM, equipment includes sound and light alarm device

5: Equipped with heat-conducting oil circulation device, the heat-conducting oil is evenly heated in the equipment, which is safer

6: The electronic control part adopts Siemens, Schneider, Omron, SMC, CKD, and other components to control

7: Equipped with an elevated frame, which can directly discharge the residue into the vat

8: Mitsubishi PLC and Mitsubishi temperature module combination, the temperature can be accurate to the decimal point

9: The equipment is equipped with a pressure control system. When the pressure exceeds 0.04 MPa, the equipment will shut down and give an alarm

10: The equipment is equipped with a 1-inch caliber safety valve to ensure that there is no pressure in the barrel

11: The equipment is equipped with an electronic dual temperature control system, the main system is damaged and there is a backup system to prevent safety hazards caused by over-temperature of the equipment

12: Equipped with nitrogen protection device, safer to use the recycling machine

13: Equipped with air detection device and window light

14: Equipped with dual level control, the main control adopts German imported liquid level

15: The barrel is equipped with Teflon coating as standard, and the conical barrel makes it easier to discharge slag

16: This equipment has been evaluated by BASF in Germany and China Design Scientific Research and Research to evaluate safety products. The equipment has many functions.

The above only lists the prominent configurations, for reference only. The equipment can be used in painting, coating, electronics, hardware and other industries. This equipment has low power, fast recovery time, and more energy saving. For customers who require recovery speed, choose this model to be more energy efficient and fast

| Model number | Feeding capacity | Power supply (ACV) |

Power (KW) |

temperature range (℃) |

Processing time (min) |

Recovery rate (%) |

Machine size (mm) |

Machine weight (kg) |

| T-400 dual system recycling machine | 250-400Liters optional | 380 | 16--32 | 50-210 | 70---100L/H | 95% | 3435*1460*2825 | 1200 |

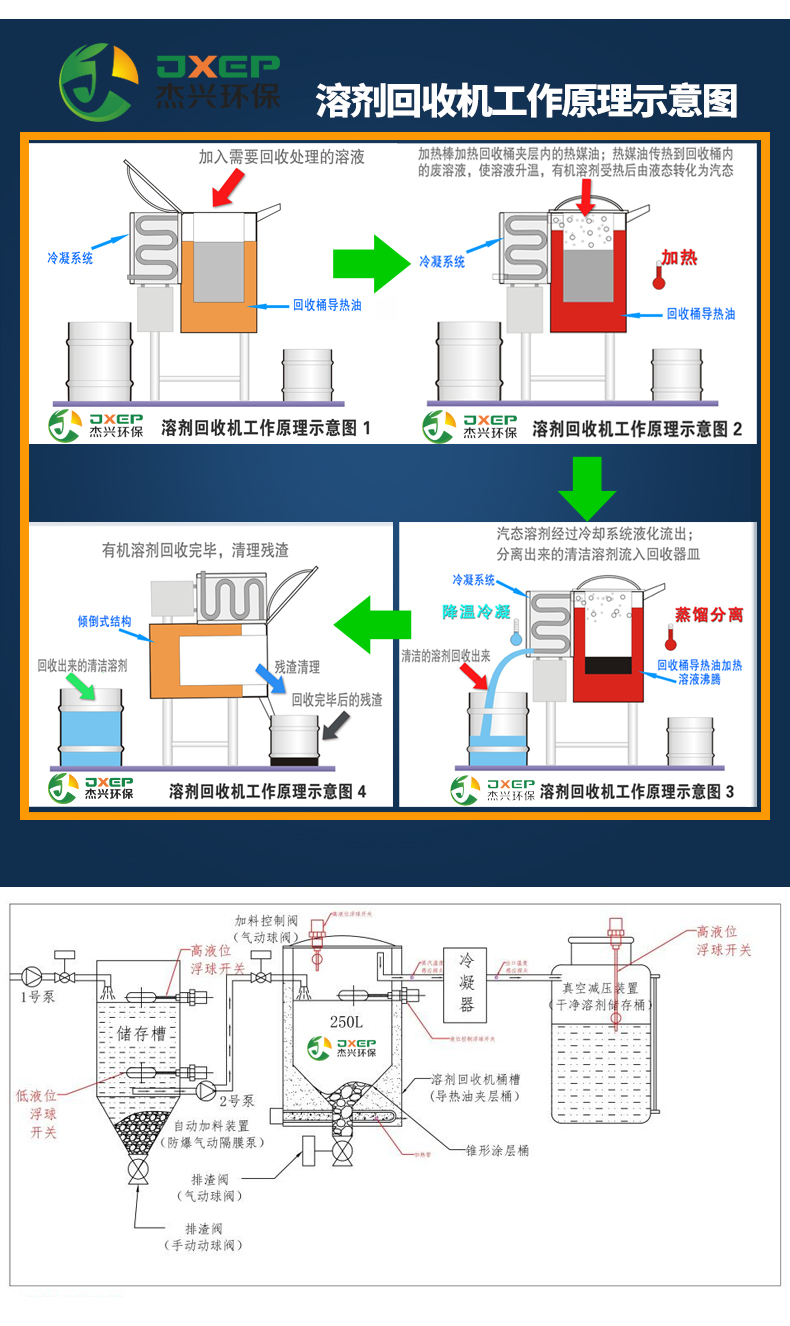

Schematic diagram of working principle

Jiexing Environmental Solvent Recycling Machine can process dozens of organic solvents

Mixed solvents: gun washing water, thinner water, banana water, gasoline, scouring oil, thinner, board washing water, hydrocarbon

Alcohol Solvent: Ethanol (Alcohol) Isopropanol (IPA) Methanol Butanol Cyclohexanol

Ketone solvents: acetone butanone cyclohexanone methyl isobutyl ketone

Aromatic hydrocarbons: benzene, toluene, xylene, trimethylbenzene, meta-xylene, para-xylene

Ester solvents: ethyl acetate ethyl acetate butyl acetate ethyl acetate methyl acetate n-propyl acetate

Halogenated hydrocarbons: dichloromethane, trichloroethylene, chlorobenzene, dichlorobenzene

Alicyclic hydrocarbons: cyclohexane cyclohexanone toluene cyclohexanone

Fatty hydrocarbons: pentane, hexane, octane

Remarks: and other organic solvents listed at the end (solvents with boiling points between 30-210 degrees can be recovered)

12 safety configurations to escort you

1. Full explosion-proof design of the whole machine and parts

Explosion-proof safety design is adopted, and the products have passed the test and certification of the China National Explosion-proof Electrical Product Quality Supervision and Inspection Center.

2. Double temperature protection

(1) When the temperature exceeds the set temperature by 10 degrees

(2) When the instrument is damaged beyond 210 degrees, the equipment will shut down and alarm

3. Double pressure protection

(1) When the pressure in the equipment barrel exceeds the pressure of 0.3KG, the safety valve relieves the pressure

(2) When the pressure exceeds 0.3KG, the pressure controller will transmit a signal and then shut down and alarm

4. Dual shutdown mode

(1) Shut down regularly

(2) The steam reaches the set value and the equipment shuts down

5. Fully automatic feeding mode

(1) Continuous feeding and continuous discharging

(2) Avoid the smell of opening the lid

(3) Avoid the problem of scalds caused by manual feeding of slag

6. The whole machine is made of stainless steel

The recycling bin is made of 304 stainless steel, with a thickness of 2MM, and the machine frame is made of 202 stainless steel with a thickness of 1.3MM, which is resistant to acid and alkali, corrosion, and long service life

7. Explosion-proof electric control box

The Jiexing R&D team is designed in accordance with European and American explosion-proof standards, and is completely flame-proof and explosion-proof, preventing all electric sparks and solvents from contacting.

8. Indirect heating

The temperature is indirectly transferred to the waste solvent in the recycling barrel through the heat transfer oil, making heating safer. The heat transfer oil is made of alkylbenzene, and it is non-flammable when heated for 360 degrees.

9. Vacuum decompression

Employing Japanese SMC vacuum generators, a multifunctional vacuum decompression pump integrating decompression, storage and discharge

10. Vacuum fully automatic

The dual-vacuum continuous feeding and discharging system can be customized according to the customer to realize automatic work from feeding to discharging.

11. 90 degree rotating slag discharge and lower slag discharge function

The recycling bin trough rotates 90 degrees to clean up foreign matter and impurities in the recycling bin, which is simple and convenient. The slag can also be discharged through the bottom of the barrel, and the slag can be discharged by pneumatic or manual.

12. Outflow liquid safety protection

When the cooling fan is damaged or the condensate is missing, and the device senses that the outflow temperature is too high, the device will shut down and give an alarm.

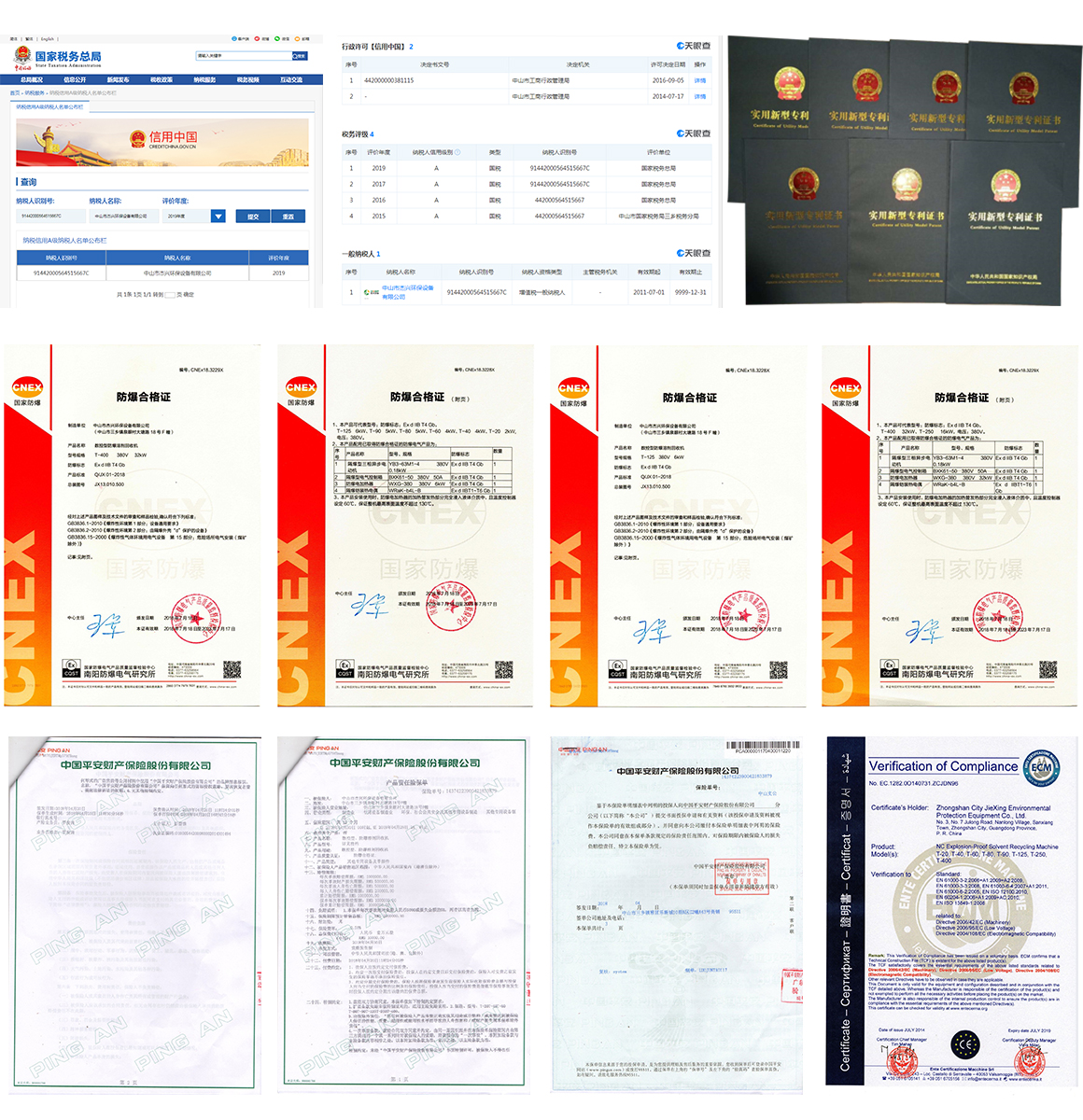

Solvent recovery machine and various patent certificates that have passed the whole machine explosion-proof certification

部分客户展示

We have been imitated but never exceeded

Jiexing Environmental Protection will continue to update to provide you with safer and more convenient solvent recovery equipment (If you have any questions about this, Jiexing can provide you with the imitator's company name and related information)

Jiexing environmental recycling rate can reach more than 95%

Thank you for visiting Kit Hing Environmental Equipment website. Your valuable opinions are the space for our future growth and improvement to provide better services. If you have any questions, please leave a message or call us. We welcome your guidance and visit at any time. Thank you for coming!

Address: No. 1 Liantang Sheung Road, Wu Shek Tsuen, San Heung Town, Zhongshan, Guangdong, China

Email:mashehui@163.com

Copyright◎2021 Zhongshan Kit Hing Environmental Equipment Co., Ltd 粤ICP备11037894号-5 BY:xinnet